Introduction

3D printing has revolutionized the world of DIY projects, allowing enthusiasts to create and customize various objects with ease. In this article, we will discuss how you can use 3D printing to enhance your projects, providing free STL files for download and a step-by-step guide on how to assemble them.

When it comes to controlling the water flow in a heating system, there are different options available. One popular choice is using a motorized register system, while another option is a solenoid. In this article, we will discuss the advantages of using a motorized register system over a solenoid system.

Utilizing 3D Printing Technology for DIY Projects

Choosing the Right Version

There are two versions available for download: one with a sensor and confirmation system and another without it. The version with sensors requires fewer supports during printing, while the version without sensors may need some additional support. Choose the version that suits your needs and download the STL files from the provided link in the description.

Gathering the Necessary Materials

If you do not have a 3D printer, don’t worry! You can purchase a complete set of parts, including screws and other components, from my online store. The link is provided in the description. For this project, we will be using the Tigre compact three-quarter-inch (25mm) valve as the base. Make sure to use this exact model for proper fitting.

Assembling the Parts

Start by removing the lever from the valve. Then, position the 3D-printed part on the valve and align it correctly. Use a 2mm drill bit to create a hole, being cautious not to damage the valve’s white shaft. After removing the 3D-printed piece, apply instant glue to the valve and attach the part, ensuring it aligns perfectly with the hole. Secure the pieces in place using screws, taking care not to overtighten them and damage the thread.

Adding the Sensor

To enhance the functionality of the valve, we will attach a neodymium magnet. Apply instant glue to the magnet and carefully place it on the gear. It is essential to ensure that the magnet is correctly positioned, as it will interact with the hall sensor module (Ky-003) later. To determine the correct side of the magnet, connect the sensor module to a 5V power source and test the magnet side that triggers the sensor. This side should face upwards on the gear.

Completing the Assembly

With the valve fully open, carefully insert the gear onto the shaft, ensuring it does not touch any other surface below. Once in place, add the locking mechanism to guarantee the gear remains fixed. This step is crucial to maintain the desired functionality of the valve.

How to Make a Motorized Valve for Water Flow Control

In this article, we will discuss how to create a motorized valve for precise water flow control. This DIY project is not only practical but also a great addition to any home automation system. With the use of a servo motor and a few simple steps, you can create a motorized valve that allows you to accurately control the opening and closing of the valve. Let’s get started!

Materials Needed

Before we begin, make sure you have the following materials:

1. Servo motor (MG 995 for high torque or any motor with torque suitable for your needs).

2. Drill

3. Instant glue

4. Rubber hammer

5. Small gear

6. Four screws with locking nuts

7. Vaselin or silicone oil

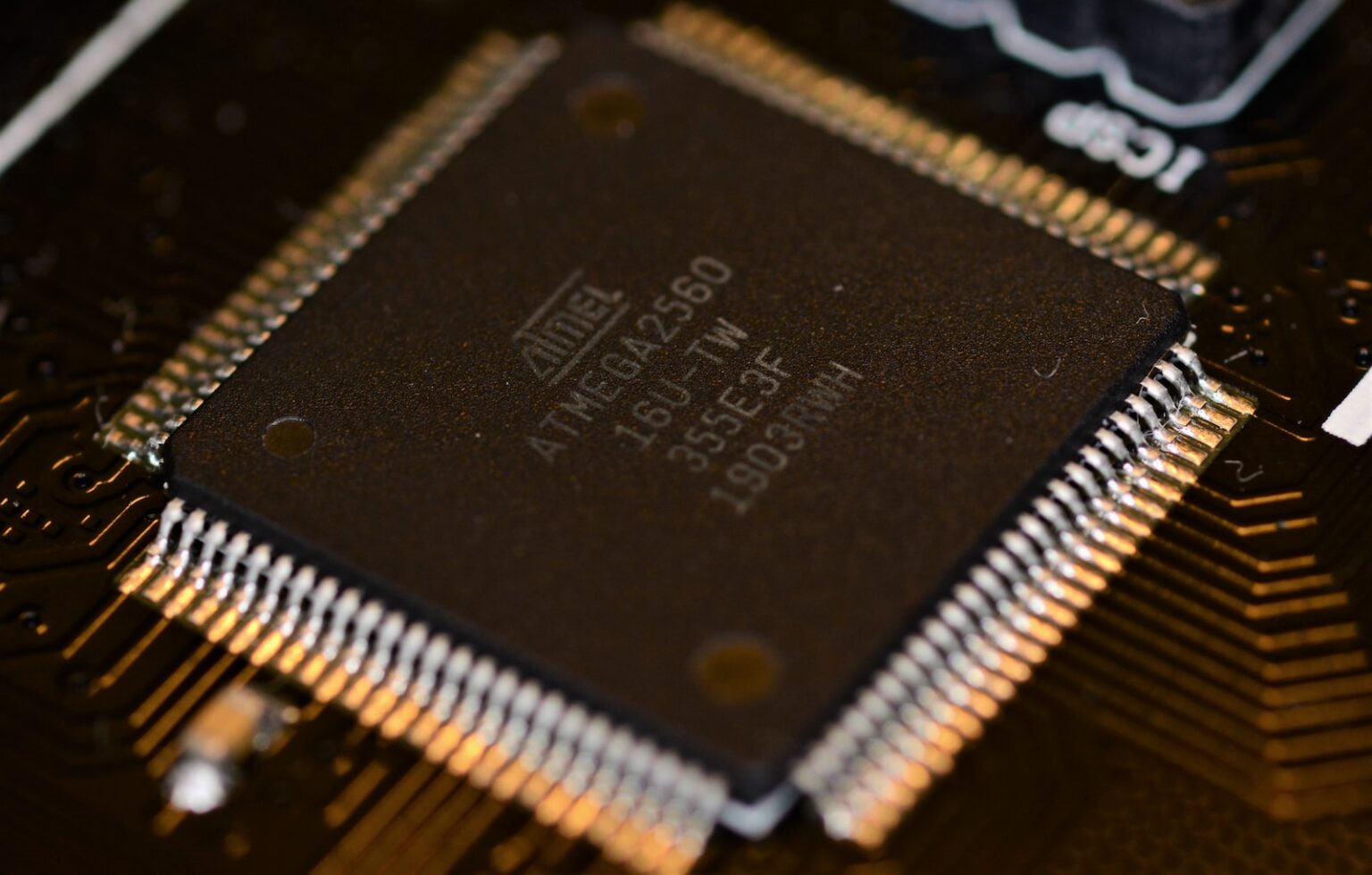

8. Arduino programmed to generate PWM signals for servo control

9. Power source (at least 6 volts and 3 amperes)

10. RY-K003 sensor

Preparing the Servo Motor

Start by marking the center of the servo motor shaft. Use a 2mm thick drill bit to drill a hole in the shaft at a depth of 8mm. Remove the shaft lock and apply instant glue to the hole. This will prevent any slippage or movement between the gear and the shaft. Then, reattach the shaft lock and tighten the screw. Be careful not to damage the gear during this process.

Attaching the Small Gear to the Servo Motor

Take the small gear and press its hole against the shaft of the servo motor. Use a rubber hammer to gently tap it until it reaches the end of the shaft. While doing this, rotate the servo motor shaft clockwise until it reaches its full range of motion. This step is essential for synchronizing the valve opening with the servo motor position. The gear should now be securely attached to the shaft with a screw holding it in place.

Assembling the Motorized Valve

Next, attach the servo motor to the base using four screws with locking nuts. This will ensure that the motor remains secure over time. Apply vaselin or silicone oil to lubricate the gears, reducing friction and increasing their lifespan. Once the motor is securely attached, you can connect it to the power source (minimum 6 volts, 3 amperes) and to your Arduino programmed to generate the necessary PWM signals to control the servo motor.

Integrating the RY-K003 Sensor

To add confirmation sensors for valve opening and closing, you can integrate an RY-K003 sensor. Start by removing the pins connected to the sensor and soldering opposite terminals in their place. This will serve as the positive and negative connections. Then, solder two long wires for the signal output and two more long wires for general power supply. Securely attach the sensor to the valve and adjust its position either by using a screw or by bending the terminals.

To prevent the nuts from coming loose and to organize the wiring, apply thread-lock glue and tidy up the wires. Now, your motorized valve with confirmation sensors is ready to be used in your incredible projects!

The Advantages of Using a Motorized Register System over a Solenoid

Energy Efficiency

One of the main advantages of using a motorized register system is its energy efficiency. With a solenoid system, the solenoid needs to be constantly powered, resulting in continuous energy consumption. However, with a motorized register system, once the energy is used to open the register, it can be turned off, and the register will remain open. This allows for significant energy savings compared to a solenoid system.

Control over Water Flow

Another advantage of using a motorized register system is the ability to control the water flow. Unlike a solenoid system, where the water flow is either fully open or fully closed, a motorized register system allows for adjustable water flow. This flexibility is particularly useful in heating systems where precise control over water flow is required.

Compatibility with Solar-Powered Systems

For those with solar-powered systems, using a motorized register system is often the better choice. Solenoid systems require constant power, which can be a drain on solar energy storage. In contrast, a motorized register system only requires power when opening or closing the register. This allows for better energy management and reduces the strain on the solar power system.

Ease of Installation

Installing a motorized register system is generally simpler compared to a solenoid system. Solenoids require additional components such as valves and plumbing connections, increasing the complexity of the installation process. On the other hand, a motorized register system can be easily integrated into existing heating systems, making it a more convenient option.

By utilizing 3D printing technology, you can enhance your DIY projects and create customized objects with precision. With the provided STL files and a step-by-step guide, you can easily assemble a valve with a sensor system. Whether you have a 3D printer or prefer to purchase a complete set, the possibilities for creativity and customization are endless.

Creating a motorized valve for water flow control is a rewarding DIY project that can greatly enhance your automation systems. By following the steps outlined in this article

While both motorized register systems and solenoids have their advantages, using a motorized register system proves to be a more energy-efficient and versatile option. With the ability to control water flow, compatibility with solar-powered systems, and ease of installation, it is no wonder why many choose this system in their heating systems. Consider these factors when deciding which system is best suited for your needs.